Have you ever wondered how a diesel generator keeps the lights on during a power outage? Diesel generators are vital machines that convert diesel fuel into electrical energy, ensuring reliable power when needed. In this post, you'll learn how diesel generators work, their importance, and their common uses in various settings.

How Diesel Generators Work

Combustion Process in Diesel Engines

A diesel generator starts by burning diesel fuel in its engine. The engine uses a process called compression ignition. First, air is drawn into the cylinder and compressed tightly, raising its temperature. Then, diesel fuel is injected into this hot, compressed air. The fuel ignites on contact without needing a spark plug. This combustion creates high pressure that pushes the piston down. The piston’s movement turns the crankshaft, producing mechanical energy.

Conversion of Mechanical Energy to Electrical Energy

The crankshaft connects to the alternator via a flywheel. As the crankshaft spins, it turns the alternator’s rotor. This mechanical rotation is the key to producing electricity. The alternator converts the mechanical energy into electrical energy through electromagnetic induction. In simple terms, moving parts inside the alternator create a magnetic field that generates an electric current.

Role of the Alternator

The alternator has two main parts: the rotor and the stator. The rotor spins inside the stator. The rotor contains coils of wire or magnets, and the stator holds coils of wire that stay still. When the rotor spins, it creates a changing magnetic field around the stator’s coils. This change induces an electric current in the stator coils. The generated electricity is alternating current (AC), which is suitable for powering homes, businesses, or equipment.

The alternator also includes a voltage regulator. This device keeps the output voltage steady, even if the engine speed changes. Without it, the voltage might fluctuate, which could damage electrical devices. The regulator adjusts the rotor’s magnetic field to maintain a constant voltage level.

Note: Understanding the diesel engine’s combustion and the alternator’s function helps in selecting the right generator size and maintaining optimal performance for your business needs.

![How Does A Diesel Generator Work]()

Key Components of Diesel Generators

Understanding the key components of a diesel generator helps grasp how it functions and how to maintain it effectively. Each part works together to convert diesel fuel into electrical power reliably.

Diesel Engine

The diesel engine is the heart of the generator. It burns diesel fuel to produce mechanical energy. This engine operates on compression ignition, where air is compressed to a high temperature, causing the injected diesel fuel to ignite spontaneously. The engine size determines the generator’s power output — bigger engines produce more power.

Alternator

The alternator converts mechanical energy from the engine into electrical energy. It consists mainly of a rotor and stator. The rotor spins inside the stator, creating a magnetic field that induces an electric current in the stator coils. This current is alternating current (AC), which powers homes and businesses.

Fuel System

The fuel system stores and delivers diesel fuel to the engine. It includes pipes, filters, valves, and a fuel tank. The system ensures a steady supply of fuel for continuous operation. Fuel system size affects how long the generator can run before refueling.

Voltage Regulator

The voltage regulator maintains a steady electrical output. It adjusts the generator's voltage by controlling the magnetic field in the alternator. Without it, voltage would fluctuate with engine speed changes, potentially damaging connected equipment.

Cooling and Exhaust System

The cooling system prevents the engine from overheating by circulating coolant through a heat exchanger. The exhaust system safely removes combustion gases from the engine through pipes, keeping the generator and surroundings safe.

Lubrication System

This system pumps oil to engine parts, reducing friction and wear. Proper lubrication ensures smooth engine operation and extends its lifespan.

Battery Charger

The battery charger keeps the generator’s starting battery charged. This battery powers the starter motor that turns the engine on.

Control Panel

The control panel lets operators start, stop, and monitor the generator. It displays important data like voltage, frequency, oil pressure, and temperature, helping maintain safe operation.

Main Assembly Frame

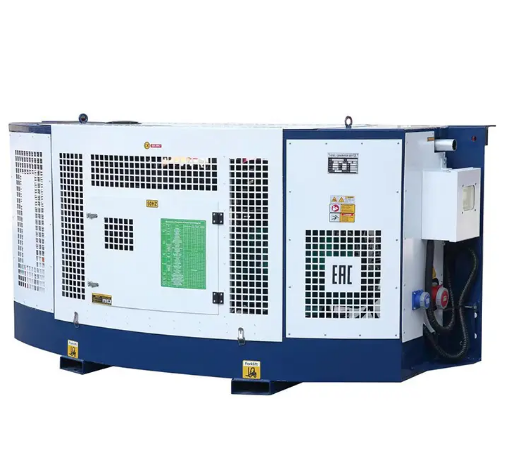

The main assembly frame holds all components together. It can be open or enclosed. Enclosed frames protect the generator from weather and reduce noise, making them ideal for outdoor use.

Tip: Regularly inspect the fuel system and control panel to catch issues early and ensure uninterrupted generator performance.

Types of Diesel Generators

Diesel generators come in various types to suit different power needs and applications. Understanding these types helps businesses choose the right generator for their specific requirements.

Portable Diesel Generators

Portable diesel generators are compact and designed for easy transport. They usually have a smaller engine and fuel tank, making them ideal for short-term use or locations without permanent power setups. You might find these at construction sites, outdoor events, or for emergency use at homes. Their portability allows quick deployment wherever power is needed.

Standby Diesel Generators

Standby diesel generators serve as backup power sources. They automatically start when the main power supply fails, ensuring continuous electricity without manual intervention. These generators are common in hospitals, data centers, and commercial buildings where power outages can cause serious disruptions. They remain on standby, ready to provide power instantly when needed.

Prime Power Diesel Generators

Prime power generators are the main power source for locations without access to a reliable electrical grid. They run continuously or for extended periods to supply electricity. Industries like mining, remote construction, or off-grid communities often rely on prime power generators. These units are built for durability and can handle variable loads over long durations.

Continuous Power Diesel Generators

Continuous power generators provide electricity non-stop, usually in places where the grid power is unreliable or unavailable. Unlike standby generators, they operate constantly to meet ongoing power demands. These are used in critical infrastructure, manufacturing plants, or remote facilities. Their design focuses on fuel efficiency and long-term operation.

Tip: When selecting a diesel generator, consider the power needs, operation duration, and location to choose the type that best fits your business demands.

Applications of Diesel Generators

Diesel generators power many different settings because they are reliable and versatile. Their uses range from heavy industry to homes, emergency backups, and off-grid locations.

Industrial Use

Industries rely on diesel generators to keep operations running smoothly. Factories, construction sites, and mining operations often need uninterrupted power. Diesel generators provide a steady supply of electricity for machinery, lighting, and safety systems. They are especially useful where power grids are unstable or unavailable. For example, a mining site deep in a remote area may use a prime power diesel generator as its main power source.

Residential Use

Homes sometimes use diesel generators as backup power during outages. In areas prone to storms or grid failures, a standby diesel generator can automatically start to keep essential appliances running. This includes refrigerators, heating or cooling systems, and medical devices. Portable diesel generators also offer temporary power for outdoor events or home improvement projects.

Emergency Backup Power

Hospitals, data centers, and emergency response centers require reliable power at all times. Diesel generators serve as backup power sources during blackouts or grid failures. They automatically activate to prevent disruptions that could risk lives or data loss. The fast start-up and durability of diesel generators make them ideal for critical emergency power.

Off-Grid Solutions

Many remote communities and off-grid facilities depend on diesel generators for continuous power. These generators provide electricity where no utility grid exists. They can run for long periods, supplying power for lighting, communications, water treatment, and more. For example, remote research stations or rural villages often use continuous power diesel generators.

Tip: For businesses relying on diesel generators, choosing the right type based on application ensures efficiency and reduces operational costs.

Maintenance of Diesel Generators

Proper maintenance keeps a diesel generator running smoothly and extends its lifespan. Regular care prevents breakdowns and ensures reliable power when you need it most. Here are key maintenance tasks to focus on:

Regular Servicing and Checks

Frequent inspections help catch minor issues before they become major problems. Check the generator’s overall condition, listen for unusual noises, and watch for leaks or loose parts. Follow the manufacturer’s recommended service schedule to maintain warranty and performance.

Oil and Filter Changes

Engine oil lubricates moving parts, reducing friction and wear. Over time, oil degrades and collects contaminants, so change it regularly. Replace oil filters at the same time to keep oil clean. Dirty oil or filters can cause engine damage and reduce efficiency.

Coolant System Maintenance

The cooling system prevents overheating by circulating coolant through the engine. Monitor coolant levels and top off as needed. Inspect hoses and connections for cracks or leaks. Flush and replace coolant periodically to avoid corrosion and maintain proper engine temperature.

Battery Maintenance

The battery powers the generator’s starter motor. Keep it fully charged and clean battery terminals to prevent corrosion. Test battery voltage regularly and replace weak or old batteries. A failing battery can prevent the generator from starting during an outage.

Load Testing

Load testing ensures the generator can handle its rated power output. Run the generator under load for a set time to verify performance and detect potential issues. This test helps confirm the generator will operate correctly during real power demands.

Tip: Schedule maintenance during low-demand periods to avoid downtime and ensure your diesel generator is always ready when needed.

Advantages of Diesel Generators

Diesel generators offer several benefits that make them a popular choice for powering homes, businesses, and industrial sites. Their key advantages include fuel efficiency, reliability, durability, and cost-effectiveness.

Fuel Efficiency

Diesel engines are known for burning fuel more efficiently than gasoline engines. They extract more energy from each gallon of diesel, which means they can run longer on less fuel. This efficiency reduces operational costs, especially for generators that run for extended periods. For businesses, this translates to lower fuel expenses and fewer refueling stops, which helps maintain steady power supply without interruption.

Reliability

Diesel generators are built to start quickly and run dependably under various conditions. They perform well in harsh environments, including extreme temperatures and dusty or wet locations. Their robust design allows them to handle sudden power demands without faltering. This reliability is crucial for critical applications such as hospitals, data centers, and emergency services where power loss is not an option.

Durability

The construction of diesel generators emphasizes longevity. Diesel engines operate at lower RPMs than gasoline engines, which reduces wear and tear. They use heavy-duty components designed to withstand continuous use over many years. This durability means fewer breakdowns and longer service life, making diesel generators a sound long-term investment.

Cost-Effectiveness

While diesel generators may have a higher upfront cost than some other types, their lower fuel consumption and maintenance needs often make them more economical over time. They require less frequent servicing and have fewer parts prone to failure. For businesses, this means reduced downtime and lower total cost of ownership. Additionally, diesel fuel is widely available and generally less expensive than alternatives, further enhancing cost savings.

Conclusion

Diesel generators operate by converting diesel fuel into electrical energy through a combustion process and mechanical energy conversion. They are reliable and efficient power sources for various applications, including industrial, residential, and emergency use. Looking ahead, diesel generators will continue to evolve with advancements in technology and environmental considerations. DONGCHAI POWER offers diesel generators that provide exceptional value through durability, reliability, and fuel efficiency, ensuring your power needs are met with high performance and cost-effectiveness.

FAQ

Q: What is a diesel generator?

A: A diesel generator is a machine that converts diesel fuel into electrical energy through a process involving a diesel engine and an alternator.

Q: How does a diesel generator produce electricity?

A: A diesel generator produces electricity by using a diesel engine to create mechanical energy, which the alternator then converts into electrical energy.

Q: Why choose a diesel generator over other types?

A: Diesel generators are chosen for their fuel efficiency, reliability, durability, and cost-effectiveness, making them ideal for continuous and emergency power needs.

Q: What are the main components of a diesel generator?

A: A diesel generator's main components include the diesel engine, alternator, fuel system, voltage regulator, cooling and exhaust systems, lubrication system, battery charger, control panel, and main assembly frame.

Q: How much does a diesel generator cost?

A: Diesel generator costs vary based on size, power output, and features, ranging from a few hundred to several thousand dollars.